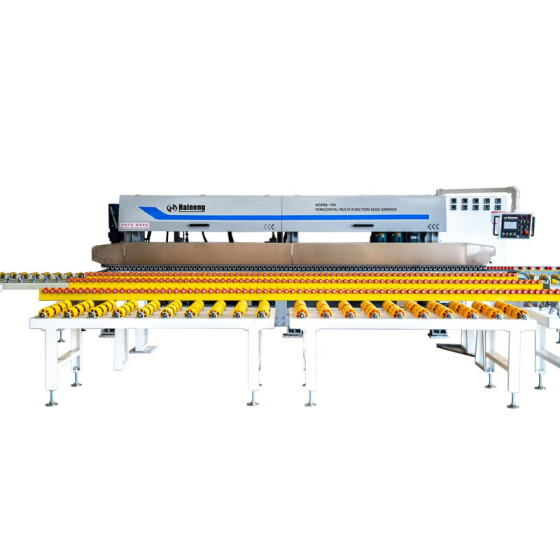

CNC Waterjet Cutting Machines

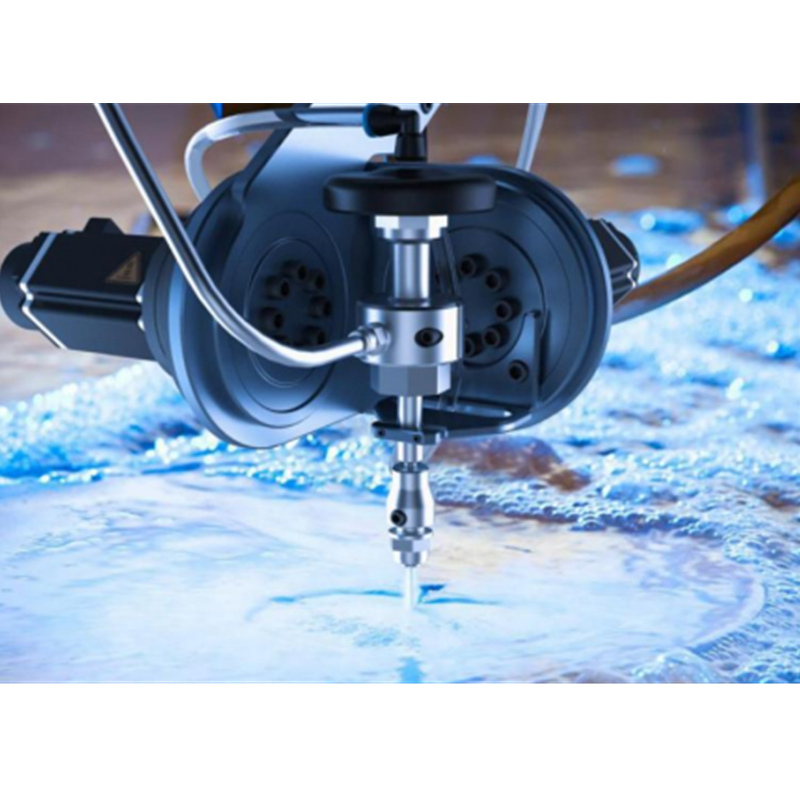

In five axis CNC system, coordination of X, while Y, Z and A, B of the two axis of rotation, the water jet cutting head can swing in any direction.

Item No.:

SKSD1515-AB

SKSD2015-AB

SKSD2515-AB

SKSD3020-AB

SKSD4020-AB

- Haineng

- Fujian

- 30 days

- 10 PCS Per Month

- Information

- Video

Product Introduction

In five axis CNC system, coordination of X, while Y, Z and A, B of the two axis of rotation, the water jet cutting head can swing in any direction. When cutting, the computer according to the real-time calculation of the density and thickness of materials by cutting the workpiece, and control the cutting head along the cutting path and operation, to achieve three-dimensional complex shape of the workpiece cutting, such as surface slope cutting, chamfering and cutting high precision conical surface circular surface complex. The water jet and achieve higher performance and bring better benefits.

Cutting edge

1 strong versatility, almost all materials can be cut.

The 2 is cold water jet cutting, cutting does not produce thermal effects, no deformation, no residue, no ablation, does not change the physical and chemical properties of materials.

3 small slot, with the characteristics of cooling cutting, can improve the utilization rate of materials.

4 cutting medium only water and natural abrasives, cutting process does not produce other substances, is clean and environmentally friendly cutting process.

5 after cutting, the cutting surface is smooth and smooth, not in the cutting process of cutting objects have any damage, you can play a lot of cutting tools can not achieve the cutting operation.

The scope of application of water jet is very wide, from the metal material to non-metallic materials, materials from natural to artificial materials, from food to household goods, basically can be cut, "universal cutting machine" reputation.

Main application areas are:

1, ceramics, stone and other building materials processing

2, the processing of glass products, such as glass parts cutting, building decoration, craft glass

3, machinery industry, metal plate cutting

4, the advertising industry signs, art pattern cutting

Technical Parameters

Machine Type | 1515 | 2015 | 2515 | 3020 | 4020 | ||

| Machine Structure | Gantry Type | |||||

Internal size of water tank(mm) | 1500×1500 | 2000×1500 | 2500×1500 | 3000×2000 | 4000×2000 | ||

Overall size (mm) | 2700×2300 | 3200×2300 | 3700×2300 | 4200×2800 | 5200×2800 | ||

3 Axis | cutting size(mm) | 1500×1500 | 2000×1500 | 2500×1500 | 2500×1500 | 2500×1500 | |

Z-Axis travel | 150mm | ||||||

5 Axis AB | cutting size (mm) | 1450×1450 | 1950×1450 | 2450×1450 | 2950×1950 | 3950×1950 | |

Rotation angle | 0-10° | ||||||

Z-Axis travel | 120mm | ||||||

5 Axis AC | cutting size(mm) |

|

|

| 2700×1900 | 3700×1900 | |

Rotation angle | ±59° | ||||||

Laser sensor | Configure laser sensors, with optional probe functionality | ||||||

Z-Axis travel | 90mm | ||||||

Cutting accuracy | ±0.1mm(Cutting tolerance is 0.2mm without deformation of the cut material) | ||||||

Cutting speed | 0.50-3.5 m/ min (Depends on the material) | ||||||

X-axis and Y-axis no-load running speed | 0-6000 mm/min | ||||||

Z-axis no-load running speed | 0-200 mm/min | ||||||

Internal diameter of sand pipe | 0.5-1.02mm | ||||||

Gemstone diameter | 0.1-0.33mm | ||||||

Longitudinal beams and cross beams | 45#Square tube welding

| ||||||

Screw rod, guide rail | Oil-filled | ||||||

Sand casting method | Self-priming sand removal | ||||||

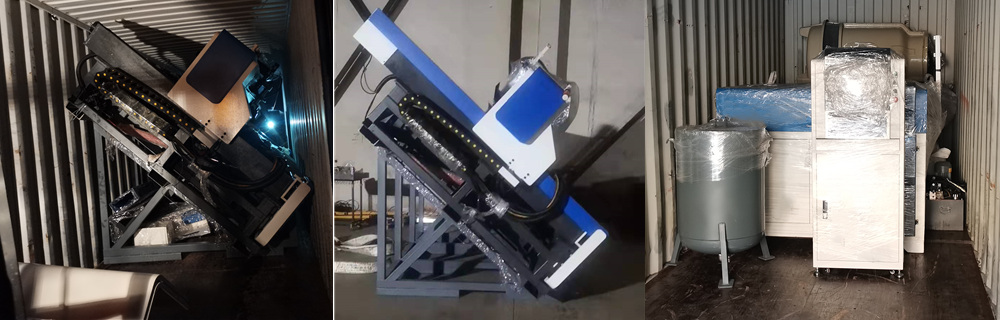

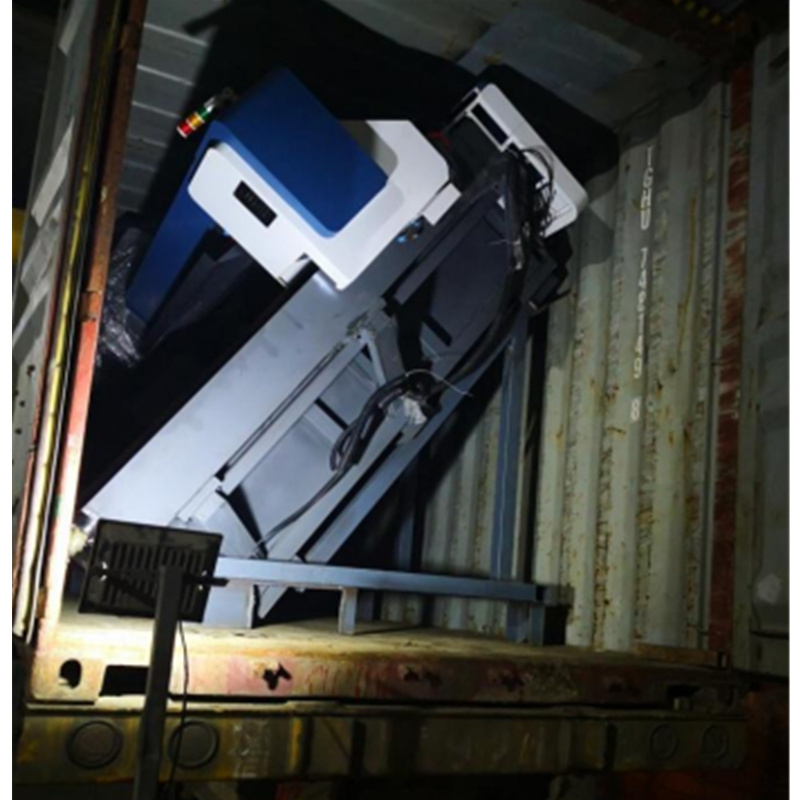

Processing

Loading